After printing is complete, CIMP-3D dedicated supporting systems help ensure that all builds are of the highest quality.

This includes CT scanning equipment to help inspect every inch of a final part, materials characterization and testing to understand the final properties of a build, and post-processing equipment to help ensure that all final parts are built exactly to specification.

Inspection Systems

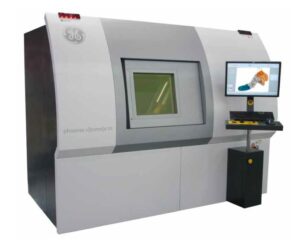

phoenix v|tome|x m 300

GE

This CT system features a dual-tube setup, possessing both 300 kV and 180 kV microfocus x-ray tubes for penetrating our additively manufactured metal parts.

The system is well-suited for the small to medium-sized parts that the majority of contemporary additive systems are capable of manufacturing, possessing a 16” flat panel digital detector array (DDA) and a rotary stage rated for specimens weighing up to 110 pounds. Specimens of up to approximately 12” in diameter and 16” tall can be scanned in a single acquisition; specimens of up to 20” in diameter and 24” tall can be accommodated by the chamber, but may require more than one scan acquisition to capture the region(s) of interest.

Analysis of the reconstructed data sets is performed with Volume Graphics VGStudio Max software, allowing not only for visual review of slices to inspect for discontinuities such as voids or inclusions, but also for advanced analysis with defect detection, nominal/actual surface comparison, wall thickness, composite fiber orientation and GD&T modules.

Phantom VEO 1310s

Vision Research

This high-speed camera is capable of capturing up to 10,860 frames per second at a resolution of 1280 x 960 pixels and even higher frame rates at lower resolutions. It can be externally triggered and synchronized with other sensors or AM equipment for detailed analysis.

When combined with the right optics, filters, and illumination, the VEO 1310s can record clear, slow-motion video of melt pool dynamics and other AM process anomalies.

VHX-7100

Keyence

The VHX-7000 Series is a fully-automated digital microscope system that enables even novice users to capture high-resolution images that rival an SEM. The Optical Shadow Effect Mode features a combination of specially designed high-resolution lenses, a 4K CMOS, and high-performance lighting that enables minute surface details to be observed and analyzed.

The seamless transition in magnification from 20x to 6000x using a motorized turret offers a stress-free observation environment. The VHX-7000 Series 4K industrial digital microscope offers the highest level of automation and best picture quality in the VHX Series. All these features and more add up to make it the best digital microscope on the market.

Edge ScanArm HD

FARO

This portable 7 axis metrology arm has a 6 foot measuring volume with an attached high-definition blue laser line probe.

The Coordinate Measuring Machine (CMM) probe allows for extremely accurate contact measurements of our additively manufactured parts. The CMM probe also helps align our as-printed parts to CAD which enables us to determine how well a part was built. The blue laser line probe gives us the ability to capture point cloud data of entire surfaces from highly complex, reflective, and organic structures.

Testing and Characterization Equipment

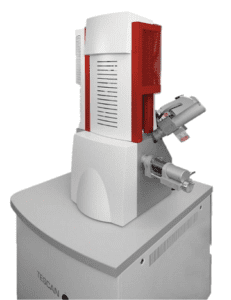

MIRA3 XMU Scanning Electron Microscope (SEM)

TESCAN

Quantax Energy Dispersive Spectroscopy (EDS)

Bruker

Additive Manufacturing Particle Analysis System (AMPAS)

RJ Lee

This system has been custom configured by RJ Lee Group and includes IntelliSEM software for fully automated characterization of additive manufacturing powder feedstock.

The system is capable of automatically and rapidly assessing the particle size distribution, shape factors, composition variation, shape distribution vs size and contaminant identification of AM (or other) powders. It features an XMU (extra-large chamber), field-emission source, variable pressure SEM with secondary and backscattered electron detectors, LVSTD secondary detector for low-vacuum operation, active vibration isolation system and a BRUKER Quantax Energy Dispersive Spectroscopy (EDS) system incorporating a 60 mm2 Silicon Drift Detector (SDD).

Wilson VH3100

Buehler

The VH3100 Vickers and Knoop hardness test system features a 3-position virtual turret with one Vickers indenter and two measurement objectives, an automated X/Y sample stage (110 mm x 140 mm travel range), a bright field overview camera for sample navigation and scanning and a powerful image analysis. The VH3100 hardness testing system provides the ultimate high capacity testing platform capable of performing 150 make and measure indents an hour (with 10 seconds dwell time) using the fully automated test program.

The VH3100 with its extensive variety of scales and magnifications excels through maximum flexibility for automated hardness testing to ASTM and ISO no matter whether a quality control production environment or in a test laboratory.

LaboPol-30 with LaboForce-100 Head

Struers

Designed for reliability and speed for manual and semi-automatic grinding and polishing in the lab or next to the production line, LaboSystem is ready for your inspection.

Labotom-20

Struers

Labotom is a simple-to-use and powerful table-top cutting machine that can handle a wide range of workpiece shapes, sizes, complexities and materials. Sturdy and reliable, it ensures maximum uptime and can be used by any operator to section workpieces quickly and efficiently, with minimal training.

The fixed cooling nozzles improves cutting quality and reduces the risk of operator error.