Penn State’s Applied Research Laboratory (ARL) has been at the forefront of developing, advancing, qualifyin...

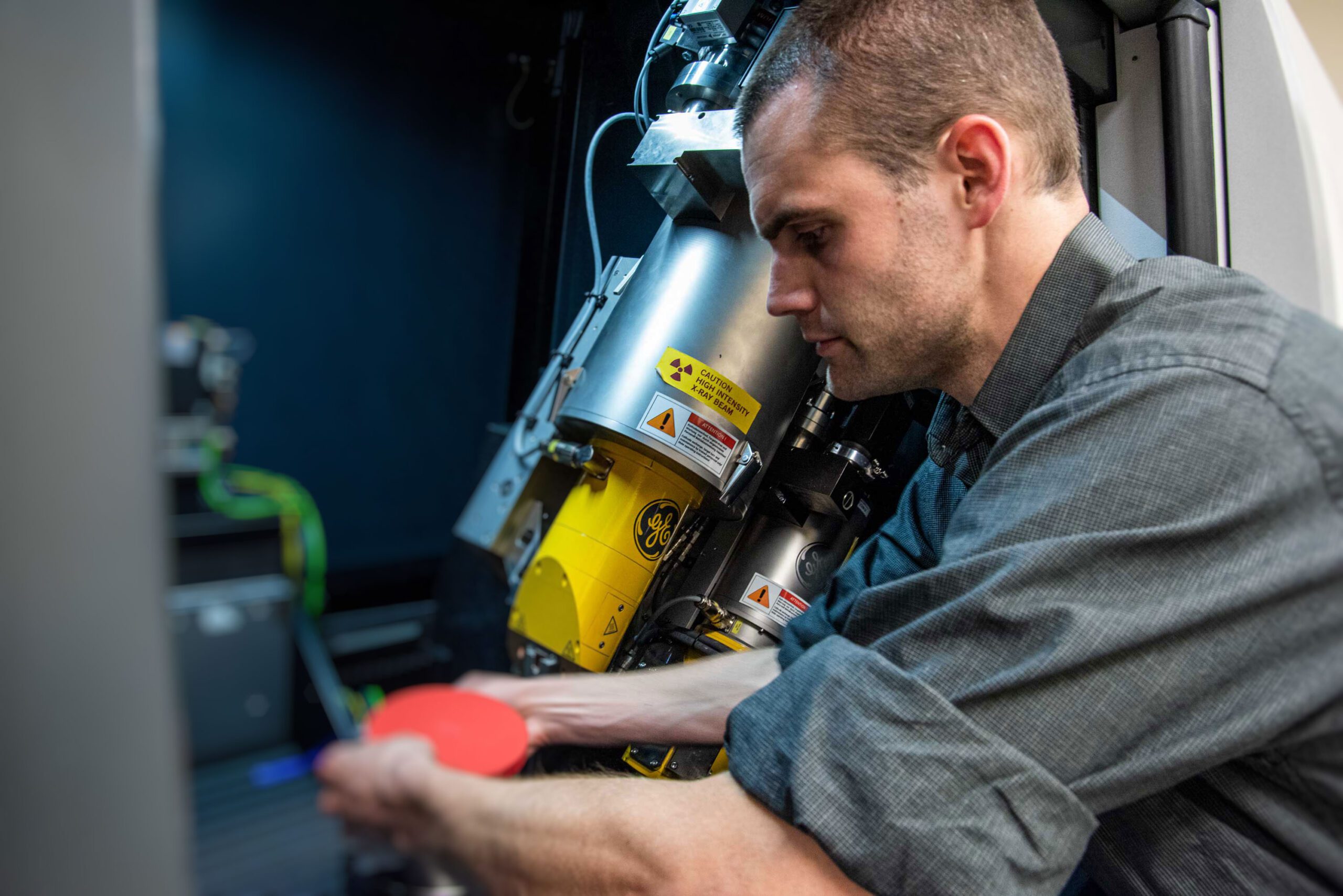

Penn State researchers, supported by CIMP-3D, have shown how ultrasound can enhance the inspectability of addi...

In a showcase of engineering excellence across the university, student organization Nittany Motorsports has pa...

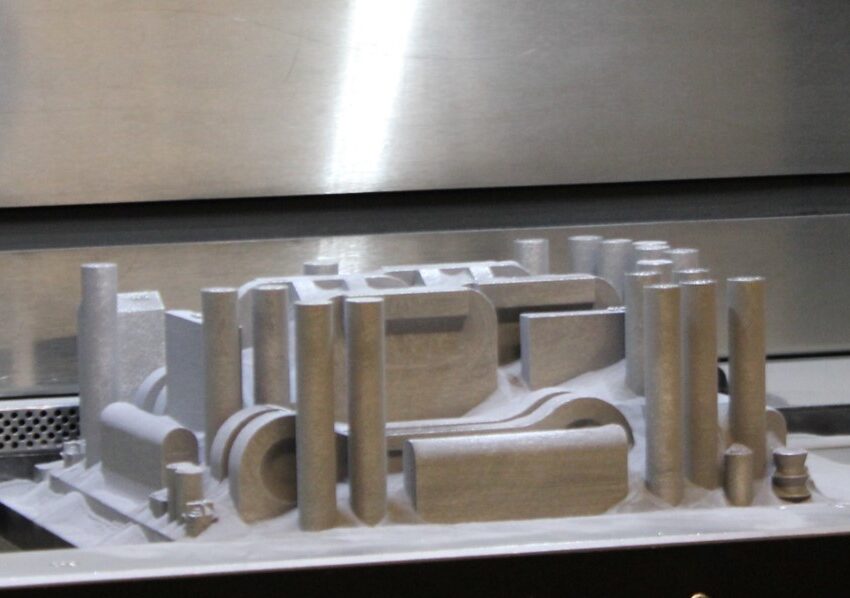

CIMP-3D researchers have developed and demonstrated innovative AM processing techniques that usher in new oppo...

With a broad mission to advance and deploy AM technology of metallic

and advanced material systems to industry, CIMP-3D seeks to:

CIMP-3D has built a reputation as a national resource for AM technology advancement. CIMP-3D serves as the additive manufacturing demonstration facility for the DoD under DARPA’s Open Manufacturing program, is a founding member of America Makes, and is an integral partner of the Penn State Applied Research Laboratory’s Institute for Manufacturing and Sustainment Technologies (iMAST), which is a U.S. Navy Manufacturing Technology Center of Excellence.