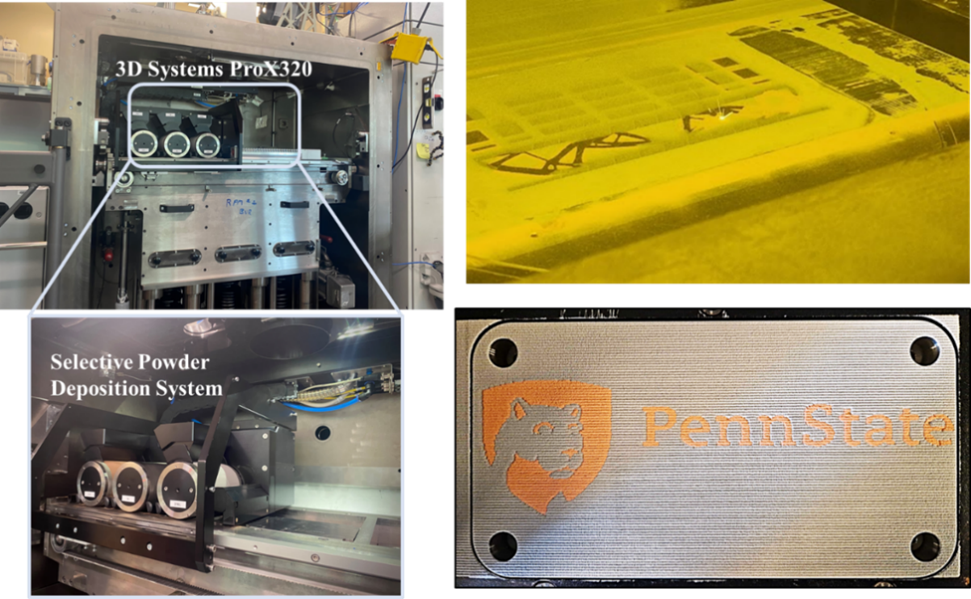

CIMP-3D continues to revolutionize additive manufacturing with the introduction of the Selective Powder Deposition (SPD) module by Aerosint, now integrated into the 3D Systems ProX320 laser powder bed fusion (LPBF) system. The technology—which can deposit three different powders within a single layer at 300 µm2 resolution—unlocks unprecedented design flexibility and material versatility. The system was acquired by Dr. Guha Manogharan, Co-Director of CIMP-3D and lead of the Systems for Hybrid-Additive Process Engineering (SHAPE) lab.

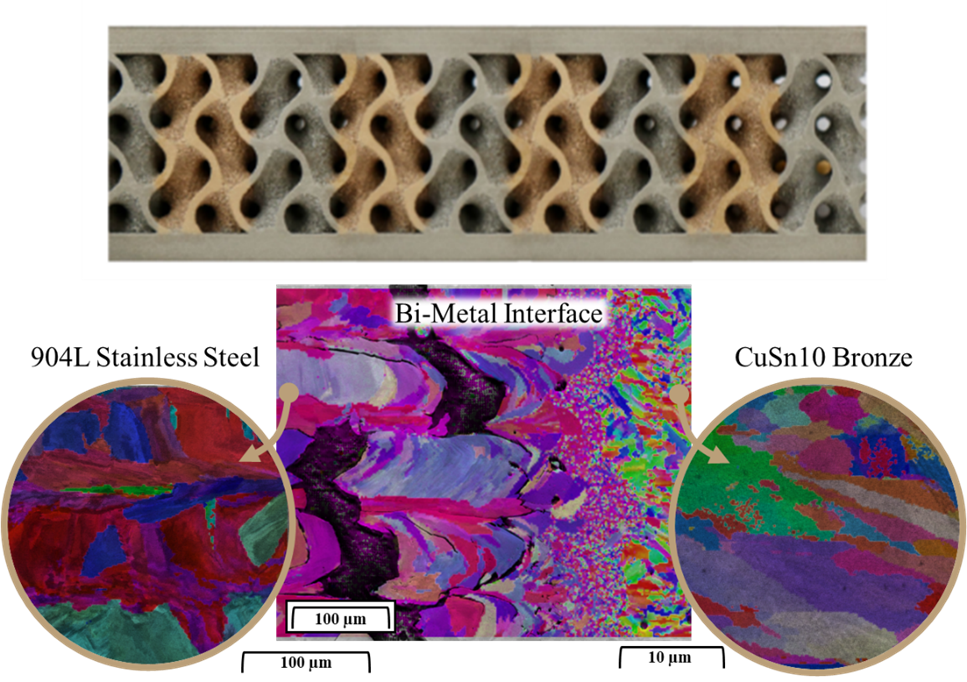

Multi-material laser powder bed fusion (MM-LPBF) delivers extreme design advantages by merging the proven design flexibility of LPBF with power of spatially-tailored materials, offering sponsors and collaborators transformative possibilities. Imagine advanced heat exchangers that integrate high-conductivity copper fins into a structural rigid stainless-steel enclosure. Or rapid, single-step manufacturing of pipe fittings that integrate a corrosion and erosion resistant liner into strong, tough, and lightweight body.

The SHAPE Lab’s acquisition of this advanced multi-material AM equipment marks a new milestone for CIMP-3D’s additive process capabilities. Collaborative research efforts are already underway with the Applied Research Lab (ARL) at Penn state, The Hast Lab at the University of Delaware, The METAL 3D Structures Lab at Utah State University, and The Idea Lab at the Imperial College of London.

We invite industry leaders to explore to possibilities of MM-LPBF for their most demanding applications. See the system in action in the video below from Additive Manufacturing Media

For more information or to collaborate, contact:

Dr. Guha Manogharan

gum53@psu.edu

Co-Director, CIMP-3D

Lead, The SHAPE Lab

Emmert H. Bashore Faculty Development Associate Professor

Associate Professor of Mechanical Engineering