Penn State researchers, supported by CIMP-3D, have shown how ultrasound can enhance the inspectability of additively manufactured metal components, earning recognition at the 2025 American Society for Nondestructive Testing (ASNT) Research Symposium.

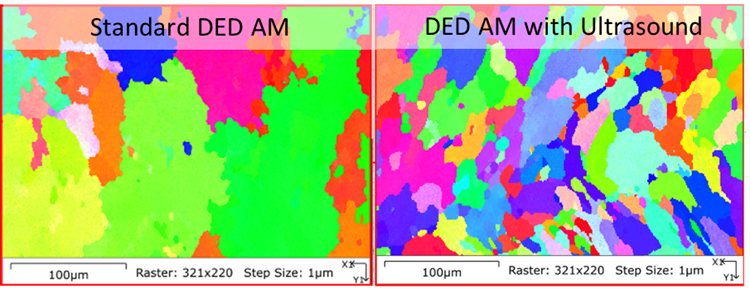

Lovejoy Mutswatiwa, a doctoral student under the guidance of Prof. Chris Kube, received the Best Student Presentation Award for his work on “Microstructure Refinement During AA7075 Additive Manufacturing for Improved Inspection via Ultrasound.” His research addresses an important challenge in Directed Energy Deposition (DED) processes: the formation of large, columnar grains that interfere with ultrasonic inspection.

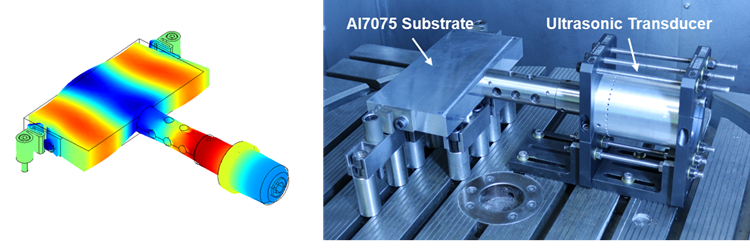

An in-situ microstructure refinement technique was realized through a collaboration between CIMP-3D and the Penn State Ultrasonics Lab (PennSUL). The process was demonstrated during deposition of AA7075 aluminum alloy on a substrate vibrating at 20 kHz using a 150 W ultrasonic transducer. This strategy refined the grain structure, improving ultrasonic inspection while also reducing porosity and mitigating solidification cracking—common issues with AA7075.

The research team comprised Lovejoy Mutswatiwa, Judith A. Todd, Edward W. Reutzel, Brady Sawyer, Christopher Schaffer, Cory D. Jamieson, Christopher M. Kube. If you’d like to learn more about these important developments, please contact Dr. Chris Kube at kube@psu.edu.