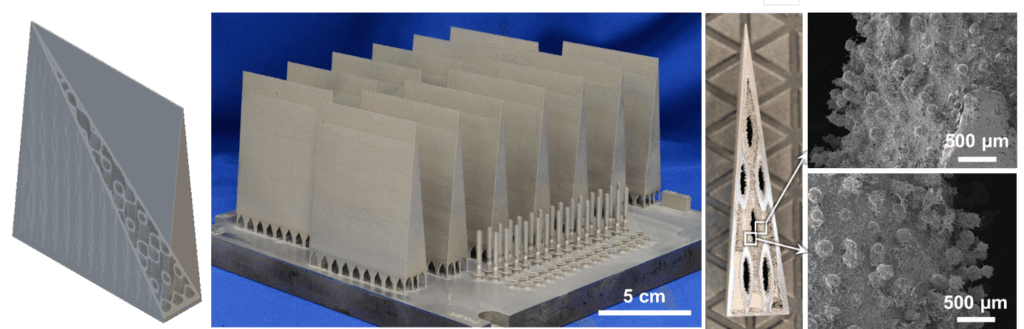

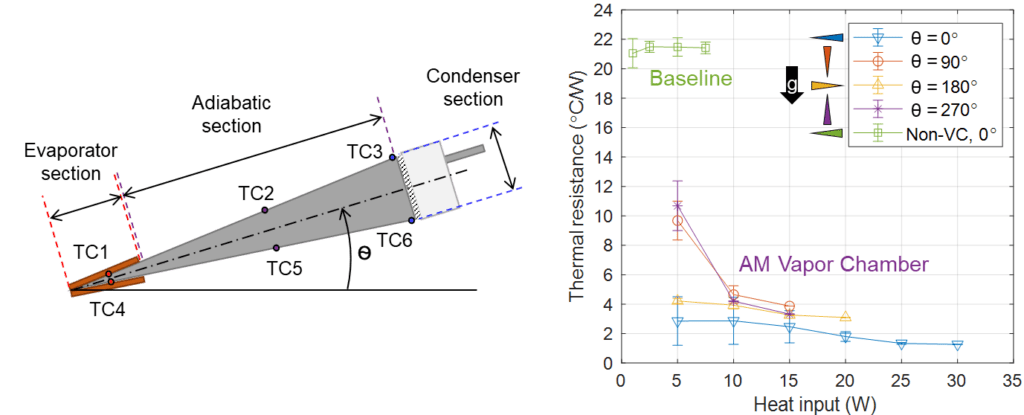

CIMP-3D researchers have developed and demonstrated innovative AM processing techniques that usher in new opportunities for thermal management. The work, published in the International Journal of Heat and Mass Transfer [1], showcases how AM can be used to produce highly complex, conformal wicking structure in nickel superalloys. The novel AM processing strategies were used to print thousands of internal micro-pillars directly onto the complex internal wicking structure.

In proof-of-concept thermal testing, the component with integrated micro-pillars exhibited an >90% reduction in thermal resistance compared to one without, demonstrating the effectiveness of the AM-enabled two-phase heat transfer devices.

This demonstration underscores the unique design flexibility offered by AM when novel processing techniques can be brought to bear. Integrating wicking structures directly into vapor chambers and heat pipes opens the door to compact, high-efficiency solutions for demanding applications such as hypersonic vehicles, aerospace electronics, and microreactors. CIMP-3D researchers are actively examining the performance of such structures, as well as their cutting-edge applications, including multifunctional systems that concurrently manage heat, convert it into electricity, and serve as integral structural elements.

[1] A. Mezghani, C. J. Dickman, E. W. Reutzel, A. R. Nassar, and D. E. Wolfe, “Additively Manufactured Inconel 718 Vapor Chamber with Conformal Micro-Pillar Wicks: A Low Temperature Concept Demonstration,” 2024, doi: 10.2139/ssrn.5061413.