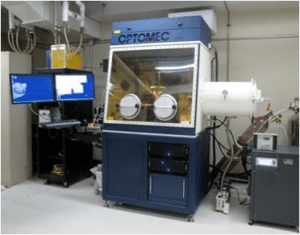

LENS MR-7

Optomec

Directed Energy Deposition System

Multiple powder-feed capabilities for deposition and full consolidation of complex components within a controlled inert gas environment.

This system provides a working envelope of 30 cm length by 30 cm width by 15 cm height. The Optomec system is capable of near-net fabrication of components and requires final machining. Although the system is capable of producing parts having complex geometries, it cannot produce geometries having significant projection or overhang without support.

This system provides a working envelope of 30 cm length by 30 cm width by 15 cm height. The Optomec system is capable of near-net fabrication of components and requires final machining. Although the system is capable of producing parts having complex geometries, it cannot produce geometries having significant projection or overhang without support.