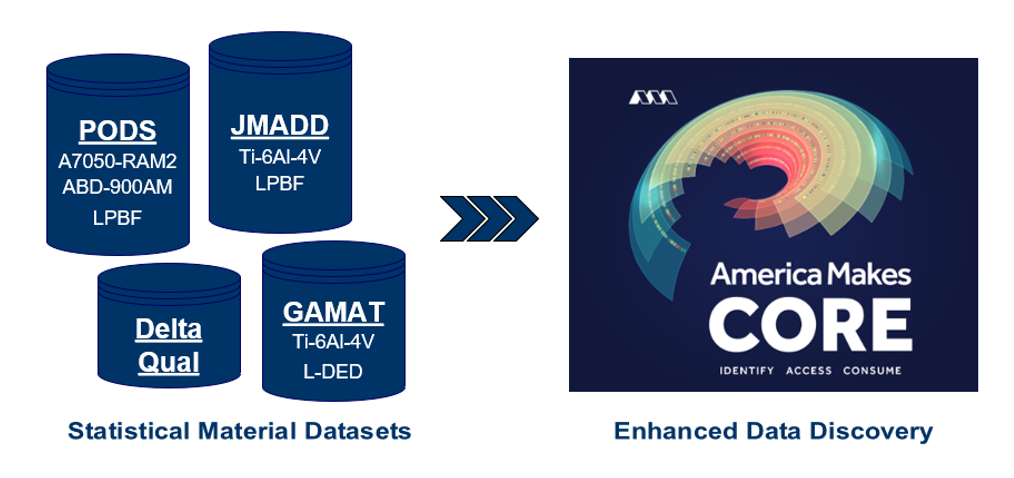

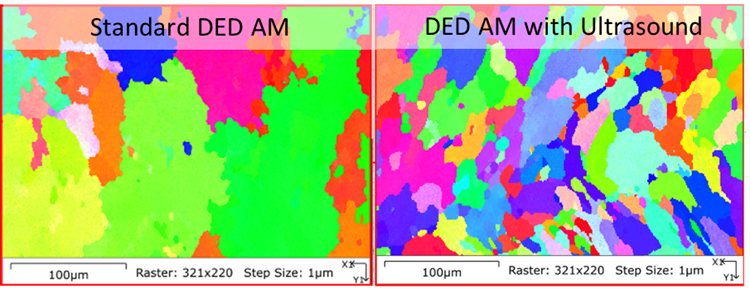

Penn State researchers, supported by CIMP-3D, have shown how ultrasound can enhance the inspectability of additively manufactured metal components, earning recognition at the 2025 American Society for Nondestructive Testing (ASNT) Research Symposium.