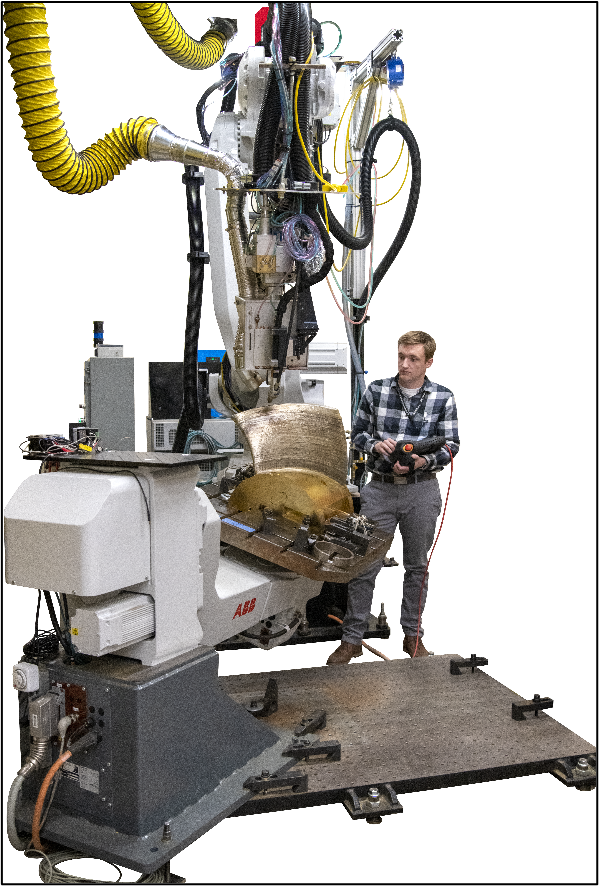

LAMAR (our Large Additive Manufacturing Articulating Robot) is ARL/PSU’s custom-engineered, large-format Directed Energy Deposition (DED) platform designed to accelerate advanced materials and manufacturing research. This next-generation system integrates high-rate metal deposition, real-time sensing, and intelligent process control into a single, flexible, mid-TRL environment—positioning it as a national asset for fundamental and applied R&D.

At the core of LAMAR is a six-degree-of-freedom articulated robot paired with a two-axis rotary positioner, enabling fully synchronized motion between the processing head and workpiece. This configuration supports a 2 m × 3 m × 3.5 m build envelope and provides exceptional freedom in producing complex geometries that cannot be fabricated on fixed-gantry systems. Oxygen-free processing is possible within an integrated argon enclosure.

LAMAR incorporates a multimodal suite of in-situ process monitoring sensors and advanced data-acquisition capabilities. Ongoing research is transforming this data into real-time, actionable insights to support qualification, automated defect detection, and inter/intra-layer closed-loop process control.

The system integrates an advanced arc-welding power supply and/or a 12 kW laserdelivered through a water-cooled, two-axis beam-scanning head for programmable energy distribution. Both wire and powder feedstock can be used, supporting deposition rates exceeding 10 kg/hr. The wire-based subsystem includes dual-wire capability for graded deposition and hot-wire capability for enhanced deposition efficiency and material control.

Uniting high-power processing, scalable motion control and intelligent sensing enables LAMAR to:

- Explore new alloys and deposition strategies

- Develop advanced monitoring for quality assessment and process control

- Fabricate large, complex geometries at high deposition rates

- Transition emerging technologies to the U.S. Defense Industrial Base

View the video on Youtube at https://www.youtube.com/watch?v=sXIDmFleJuE

Researchers, industry partners, and agencies interested in collaborative projects—fundamental or applied—are encouraged to connect with CIMP-3D.

Contact us about advanced manufacturing at Penn State:

https://cimp3d.org/about/