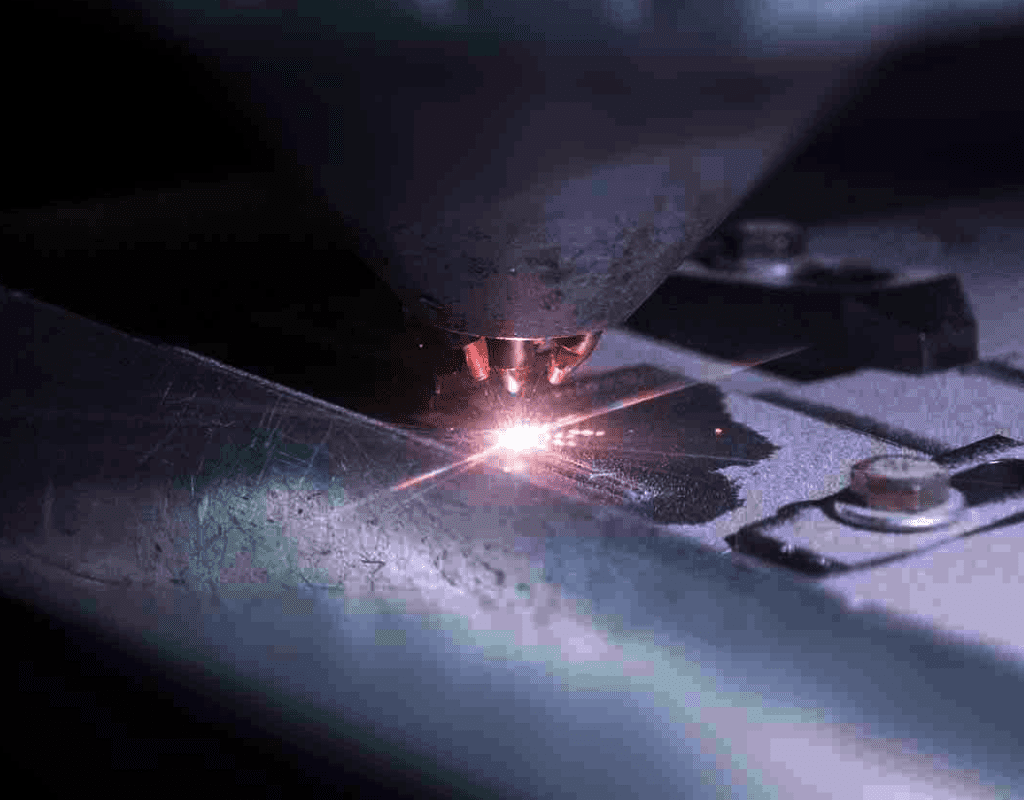

Penn State’s Applied Research Laboratory (ARL) has been at the forefront of developing, advancing, qualifying, and transitioning Cold Spray technology for repair and part fabrication to U.S. defense sponsors for more than a decade. This innovative technology enables rapid, cost-effective repairs and fabrication of critical components, ensuring operational readiness for military assets.