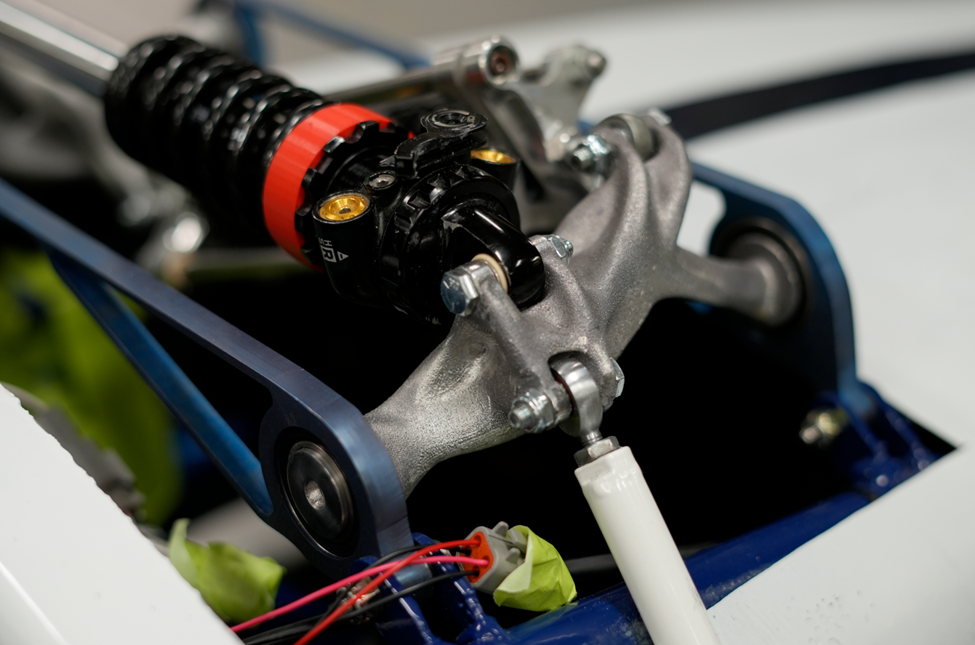

In a showcase of engineering excellence across the university, student organization Nittany Motorsports has partnered with CIMP-3D and 3D Systems to revolutionize their suspension system with the power of additive manufacturing. Competing annually against 100 other student racing teams at Formula SAE Michigan, Nittany Motorsports found that their previous suspension bell crank design cracked after weeks of abuse. A stiffer and more durable solution was needed to transmit wheel motion to the damper.

Using Autodesk Fusion 360 Generative Design, students overhauled the previous car’s bell crank, resulting in a 320% increase in stiffness with equivalent mass. This optimization technique organically links predefined mounting points, ensuring the all load cases are accounted for. The resulting complex geometry was printed on 3D Systems’ DMP Factory 500 at CIMP-3D, easily fitting 4x 10” long parts in a single build. AlSi10Mg was selected for its strength to weight ratio, a critical consideration in motorsports.

This collaboration highlights the range of possibilities when advanced computing, additive manufacturing, and student ingenuity all come together under one roof. CIMP-3D and 3D Systems are looking forward to seeing the improved car on-track this summer.

If you would like to learn more about Nittany Motorsports, feel free to contact team captain Adrian Michael (arm6897@psu.edu) or follow the link below to their website.

Nittany Motorsports | Formula SAE